Air energy heat pump drying equipment is a common equipment used in the production and processing of materials and products in the pharmaceutical, chemical, food, agricultural and sideline products, aquatic products, light industry, heavy industry and other industries. Air energy heat pump drying equipment generally has air energy heating devices. Drying equipment with circulating fans can be called hot air circulating drying equipment, because no matter what the structure of the drying equipment, the wind direction is horizontal or vertical, in the final analysis, it is hot air inside. Circulating flow, so it can be commonly referred to as hot air circulation drying equipment.

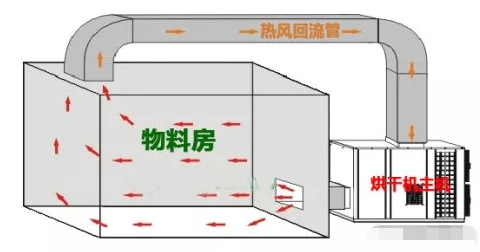

The air circulation system of the hot air circulation drying equipment adopts the forced air circulation method of the fan. After the air is heated by the heater, it is sent to the drying equipment, and then part of the used air is sucked into the air duct to become the air source for recirculation and heating. While ensuring the uniformity of the indoor temperature, forced ventilation is used to make the material dry evenly.

Advantages of air energy heat pump drying equipment

1. Economical and practical, high output; it can dry a variety of materials, the drying temperature is adjustable, and the drying process can be set to a suitable temperature; the drying capacity is large, and the investment benefit ratio for the production enterprise is much greater, so many The enterprise chooses because of its low price and good quality;

Schematic diagram of hot air circulation drying

2. The whole machine has low noise, stable operation, controllable temperature, convenient installation and maintenance, and simple and easy to use; the hot air circulation drying equipment can be used without complicated operation. If the parts are damaged, the replacement is also very simple. An ordinary electrician can complete the repair, and if there is a lack of functions that need to be supplemented in the future, the transformation is relatively simple;

3. The hot air circulation drying equipment has a wide range of applications and can dry various materials. It is an ideal general-purpose drying equipment.

4. The effect of energy saving and emission reduction is good, most of the hot air is circulated in the equipment, with high thermal efficiency and energy saving. We know that the more products that the same amount of energy can produce, the more energy-efficient it is. The definition of energy-saving is: the less energy used than other equipment, the higher the output.

Whether hot air circulation drying equipment can ensure uniform drying of materials is an important technical indicator of hot air circulation drying equipment, and also a key factor affecting product quality; and the air pressure balance of hot air circulation drying equipment is another hot air circulation drying equipment. Design key.

At present, there are more than 600 hot air circulation equipment produced by many domestic manufacturers. Compared with the past, the technical level has been greatly improved. However, it has compared with world-renowned manufacturers in terms of machining accuracy, monitoring level, design and development, and equipment control. Compared with the remaining gap.

Therefore, how to improve the air pressure technology level of hot air circulation drying equipment in our country can produce advanced drying equipment, and how to achieve accurate monitoring of air pressure according to process requirements and timely feedback, so as to further improve product quality. Become the focus of research by manufacturers.